Real Jets, Real Cheap -

20th Century technology on a 19th Century budget

[Part I]

Interview with 'Tundra Man'

_____________________________________________________

Note from the Editor:

Many hobbyists are first attracted to pulsejets because of their

seemingly cheap and simple construction. These people are then

shocked when they peruse the Web and find jets on E-Bay costing

hundreds of dollars. Although Bruce Simpson's advanced designs

and David Brill's zinc castings are beautifully designed objects,

they might be considered too pricey for the average backyard

experimenter. Two regular participants at Kenneth Moller's jet

propulsion forums have found some solutions for the penny-pinching

powerplant designer. Read this and the following interview to find

out how they managed to build some astounding machines on some

astoundingly thin budgets. - Larry Cottrill

_____________________________________________________

The Tundra Jet

['Tundra Man' Mike Kirney, interviewed by Larry Cottrill]

The first jet project in our 'Cheapskate Homebrew Showcase' comes

from Mike Kirney, of Renfrew County, Ontario. He is known to

many on Kenneth's forums as "Tundra Man". After reading and

posting on the forum for over two years, he finally decided to

take the plunge and build himself a 1/3rd scale Argus 014 replica.

[Editor's note: The Argus was the engine which powered the famous

V-1 "Buzz Bomb" which Germany used against Great Britain in World

War II. Though primitive by today's standards, the V-1 can

probably legitimately be considered the first production "cruise

missile" ever launched.] According to Mike, The only materials he

purchased for this working model were a 3 x 6 foot piece of 22

gauge steel sheet, a 6 by 50 inch roll of 0.005" stainless steel,

and two rods, 1/8" x 36" [one cold rolled steel, and one brass] -

and ended up with more material left over than what he used for

his engine!

Our interview with Mike took place a few weeks ago [mid-April,

2003] - here's what he had to say about building his mini-Argus

engine:

|

ALL WELDED UP AND NO PLACE TO GO

The fully welded tailpipe assembly of Mike Kirney's

'Tundra Jet'. The square plate at the top end of

the pipe in this photo is the not-quite-finished

'front plate', which provides the mounting surface

where the valve plate will ultimately be attached.

Photo Copyright 2003 Mike Kirney

VIEW LARGE IMAGE

|

jZ: Welcome, Mike! All right, let's get started. How did you

first become interested in pulsejets?

Mike: Back in '99, I was an aircraft maintenance student in

community college. A passing mention was given to pulsejets in

my powerplant textbook. Although the text claimed that the

pulsejet had no practical value as an aircraft powerplant, the

idea of producing hundreds of pounds of thrust from a simple duct

and valve device captivated me. I had no idea how they worked or

what sort of operational idiosyncracies they presented until I

found Kenneth's forum online, a year later.

jZ: How much have you spent on materials for your first engine

project, the 'Tundra-Jet'?

Mike: The steel sheet was $40 CDN, the roll of stainless shim was

$30 and the rods were seven bucks each, for a grand total of $84

CDN. I still have more than 2/3rds of the sheet left and about

4/5ths of the roll of shim. If I bought just a couple more rods, I

could make at least two more Tundra-Jets from the leftover

materials.

jZ: Tell us about the design of this pulsejet.

Mike: I decided to shoot for a duct length (behind the valves) of

100 cm. I just divided all the dimensions of the original Argus

by 3.3 - many forum members advise against such a simplistic

approach but it seemed to make the most sense to me. I wasn't

looking to make a lot of thrust, as I intended to use my jet for

melting snow in my driveway, plus, by adding length to the

tailpipe, I can change the operational characteristics.

HANGING LOOSE

An early shot of Mike's beautiful hand-formed pipe

sections, carefully stacked together before any

welding. This does indeed look almost identical to

the original Argus engine pipe -- only the scale of

surrounding objects reveals the truth.

Photo Copyright 2003 Mike Kirney

|

VIEW LARGE IMAGE

|

|

|

jZ: What about the valve-holder? I know Your intake is a sort of

square steel frame 12 cm on each side, enclosing a grid of

more-or-less square cells to contain the reeds.

Mike: The valve array took the most work to design. I figured my

jet was too big for petal valves. Had I used them, each petal

would have wound up being almost 7 cm long! I wanted to use the

22 gauge sheet for as much of the jet as I could. Eventually I

devised an interlocking set of 10 steel rectangles with tabs and

slots cut in them. The horizontal pieces have two holes drilled

in them, one behind the other, to form a figure-8. I cut pieces

of steel rod 14 cm long and knocked them into the rear-most holes.

These rods I brazed in place. They serve as the permanent half

of valve holders. After placing the reeds in their respective

positions, I then knocked the brass rods into the front holes.

The valves are thus held in place between the two rods, the brass

ones easily removable with a punch pin for reed replacement.

jZ: How will you keep the brass rods in place? I mean, I can

see vibration gradually working them loose, or something.

Mike: I think I'm going to lash them to the steel rods with wire

at each end and then tin solder it all in place. The solder can be

easily removed for maintenance.

![Setup of the valve plate [unbrazed] (c) 2003 Mike Kirney](Mike_setup_valveplate_crop1_small.jpg)

|

A THOROUGH GRILLING

The pieces of the valve grid, carefully set up

before brazing it all together. The steel rods are

vertical in this shot; the brass rods aren't in

place, but would be hidden behind the steel rods.

One folded reed will form a back-to-back pair of

valves in each cell.

Photo Copyright 2003 Mike Kirney

VIEW LARGE IMAGE

|

|

jZ: What did you have to do to actually fabricate your reeds?

Mike: I cut them from the 0.005" stainless shim with ordinary 8

inch long scissors. Each rectangular reed is 6 cm long and 1.5

cm wide. These pieces are bent in the middle so that they rest

like saddles on the steel rods in the array. Each reed

effectively becomes two valves when the brass rods are hammered

into place.

jZ: OK -- let's make sure I really have an accurate mental picture

of this. We have a steel rod permanently set. Each valve reed is a

rectangle folded in the middle to form a V-shaped piece. The point

of the 'V' rests against the rear side of the steel rod, then the

brass rod is slid through behind - or inside - the 'V' to lock it

against the steel rod in front.

Mike: That's it.

jZ: How did you handle the hot metalwork? I believe you've said

you used conventional torches to do the brazing and welding.

Mike: Yes, I did. The first thing I did was clean an area of the

steel sheet with varsol and acetone to get all the grime off.

Then I sprayed it with a light coat of grey automotive primer.

This allowed me to draw easily visible lines on it with an HB

pencil. I used a ruler and a triangle to lay out two rectangles,

which I cut out with a pair of compound leverage shears. After I

removed the primer and pickled the pieces with muriatic acid, I

washed them with dish detergent and water and rolled them by hand

into cylinders which would become the combustion chamber and

tailpipe of my jet. I used an oxyacetylene welding torch to do

all the welding and brazing and some of the cutting.

A BRAZEN ATTEMPT ...

Here's the grid after brazing all the connection

points. Brazing is not necessarily beautiful in its

finished state; the technique is similar to silver

soldering, but at a higher temperature. It is quite

strong, though not equal to welding.

Photo Copyright 2003 Mike Kirney

|

VIEW LARGE IMAGE

|

|

![The entire valve plate completed [brazed] (c) 2003 Mike Kirney](Mike_brazed_valveplate_crop1_small.jpg)

|

jZ: But you cut the sheet metal with hand shears ... wow.

Weren't the cut edges awfully rough and distorted?

Mike: Yes, they were. I cut all my pieces a millimetre or two

oversize and then I filed the edges down to the pencil lines with

a 9" bastard file and an 8" mill file. The shearing and filing

took the most physical energy of all, especially the shearing.

Sometimes I had to brace the shears on my basement floor and step

on them to make the cuts, especially when I was deep into the

material.

jZ: You said you rolled your pieces by hand? Surely you must have

used implements of some kind ...

Mike: I did. I used 4" lineman's pliers to bend one edge of the

rectangle downwards slightly. Then I placed two 1" dowels, one on

either side of the bend and curled my fingers around the inside

dowel. I just rolled up the steel like a piece of paper.

jZ: Like a piece of paper ... hmmmm, right ...

Mike: Well, that's how I got the first edge started anyway. I used

a variety of techniques to form the cylinders. In my mind's eye I

would break up the circumference of the cylinder into quadrants.

I would alternate quadrants, clamping the sheet between the dowels

and bending one quadrant in a little, then the other, all the way

around, until the edges to be butted were about 5 - 8 mm apart.

Then I rolled the bent edge under the flat edge and presto, I had

rough cylinders. I used a bit of 1/4" rope as a way to apply

uniform pressure to cinch the edges together too.

|

FIRST TRY AT WELDING

Another picture from very early on in the project:

The combustion chamber cylinder, with Mike's first

weld [well, the first in a long time, anyway]. Looks

awfully good to me.

Photo Copyright 2003 Mike Kirney

VIEW LARGE IMAGE

|

jZ: Was it difficult to weld your cone and cylinders?

Mike: I did practice a little before I started - it was the first

time I had picked up a torch since college. I used a #0 tip and

about 4 psi on the acetylene. My oxygen regulator was designed

for cutting so it was hard for me to tell just how much pressure

I had in the hose. I estimate about 7 or 8 psi. I used 1/16"

mild steel rod for the welding and 3/32" flux-coated brass rod for

the brazing.

jZ: With a higher oxygen pressure like that, I'd guess you must

have blown through a few times!

Mike: Not really. First I put a tack weld every 12 cm or so down

the length of the piece. Then I heated the rod just enough so

that it would get droopy and stick to the edges to be welded.

After I had laid down a few inches of rod this way, I would go

back and puddle it all together with the base metal. The biggest

problem I had was my workpieces warping and the edges overlapping,

especially with the long tailpipe. This really freaked me out at

first, but in the end it all turned out okay. After welding, I

shaped the cylinders a little more by hammering them over a scrap

piece of wood and squeezing them in my hands and between my knees.

jZ: What about the cone? A lot of people think they know how to

lay out a cone, but then after they roll it together and weld it

up, they find out they were way off the mark!

Mike: That nearly happened to me. Thank God for Hank bringing it

up on the forum. It was his fortuitous comment that made me

realize that I had no idea how to lay out a flat pattern for a

truncated cone. I did a websearch and found a site with a really

good method based on trigonometry. Using that method, I made a

template which I traced onto a piece of cardboard. Then I traced

that onto the steel sheet. I refined their explanation a little

and put it up on my webspace:

http://home.ca.inter.net/mkirney/cone.html

jZ: Why didn't you just use the well-known program called "Cone"?

Mike: I thought about it, but I realized that my developement

would be too big to print on a single sheet of letter-sized

paper. Believe it or not, I actually enjoy doing trig. I wanted

to learn the principles behind the cone development so I could

apply them to other shapes as well.

jZ: You ENJOY trigonometry? Are you psychotic, or what?

Mike: Well, lets just say I am socially functional but as yet,

psychiatrically undiagnosed.

jZ: How can you enjoy trig? Seriously, Mike ... I detect

illness ...

Mike: Hey c'mon Larry. I don't make fun of your little tiny jets.

jZ: Tiny? TINY!!! My engines will ... uh ... fit into any budget

and lifestyle ... they'll uh ... become a novel addition to any

home environment ... um ...

Mike: Yeah, right ... well then, just cut the jive about my trig

fetish, OK?

jZ: Oh, all right, we'll try to get back on topic here. You

mentioned to me earlier that you actually did some cutting with

the welding torch. Isn't that ... illegal or something? [laughing]

Mike: Nope. I used a #2 tip to cut out the circles for the

valveplate and the frontplate on the duct. It was very quick and

easy but I had to file off the inside edges afterwards.

jZ: Yes, actually my dad had a rather nifty trick for that. He'd

heat a spot up red hot with the torch, then quickly valve off

the acetylene and just start moving it along, letting the oxygen

stream keep the cut going. It was an amazing thing to see! Now,

you have a frontplate that acts as a mounting surface for your

valveplate, right? That's pretty heavy stuff compared to the

sheet metal chamber -- I mean, welding the frontplate to the

combustion chamber must have been a bit of a blacksmith's

nightmare, I would think.

Mike: Nah, it was easy. I used the same technique as before

where I laid down the rod and then puddled it after. There was

some overlap left on the inside of the hole so I just puddled

that down to a nice round edge. That joint is probably the

strongest one on the whole engine.

jZ: How do you attach the valveplate to the rest of the jet?

Mike: I use eight 5/16" bolts with nuts and lockwashers. They

are about an inch long so they should accomodate any gasket I might

have to use.

TAKING THE LONG VIEW

Looking rearward through the fully welded engine,

as seen through the mounted valve plate grid. Note

the slight out-of-round distortion -- while almost

inevitable when fabricating all the parts by hand,

this should have absolutely no effect on running

or performance.

Photo Copyright 2003 Mike Kirney

|

VIEW LARGE IMAGE

|

|

|

jZ: So ... when do we get to hear this beast run?

Mike: Well, the chinook just blew through town today so that

usually means we're gonna get one more snowfall this week, then

the frost is over until Hallowe'en. I'm hoping I'll have

everything good-to-go by the end of April. I'm trying to adapt a

fuel system from a 1 lb. propane bottle and an old welding torch

I found in my shed. I have an old regulator too. I'm thinking

about just using fireplace matches to light the thing, as

electric starting seems kind of decadent right now.

jZ: Oh, before I forget ... thanks for getting an interview for us

with our friend, Mark 'Thixis'. I'll try to publish that right along

with this one.

Mike: Yeah, Mark's always fun to talk to -- and that dude really

builds some weird stuff ... he gets it to run, though!

jZ: Well I hope you keep in touch, Mike. I mean, we're going

to be hanging from the rafters by our fingernails waiting for your

test results! The Tundra-Jet sounds like it's bound to cause a shop

class revolution.

Mike: [laughing] Ha! Shop class revolution -- I could really dig that!

Thanks for interviewing me, Larry. Hey man, I saw some empties under

your front deck. Would you mind...?

jZ: What, those old Pepsi cans? Uh, yeah, whatever ... go ahead

and take 'em.

Mike: Thanks, man ... you just never know what you can use. See,

I just now thought of this little jet where you'd ...

_____________________________________________________

Photo Credits:

All photos in this article were provided by, and are property of,

Mike Kirney.

_____________________________________________________

|

Mike Kirney, of Renfrew County, Ontario, Canada has been

interested in pulsejets for several years, but only started

to build his own a few weeks ago. Mike has also played guitar

[the instrument shown here is a Godin electric from Quebec],

piano, flute and alto sax. He has visited all ten Canadian

provinces and about 20 States of the US, and once bicycled

from Vancouver, BC to San Francisco, CA in nineteen days.

He is very interested in alternative power sources, especially

some new uses for steam. Mike answers to the nic "Tundra

Man" and can be reached at ame2000@lycos.com

Photo Copyright 2003 Mike Kirney

|

_____________________________________________________

|

Real Jets, Real Cheap -

20th Century technology on a 19th Century budget

[Part II]

Interview with Mark 'Thixis'

_____________________________________________________

Note from the Editor:

There's more than one way to build working pulsejets 'on the

cheap'. In the previous article, Mike Kirney showed how low cost

materials can be used effectively; however, Mike's building

techniques still require a lot of manual skill and effort -

especially, skills in metal forming and gas welding. The

following article shows a completely different method. This

does not produce lightweight 'flight engines' [which is what a

lot of us kind of expect a jet engine to be] but rather, simple,

extremely rugged structures, built mostly of ordinary plumbing

parts -- what this builder calls a 'Tinker Toy' approach. As

you'll see, it's something really different! - Larry Cottrill

_____________________________________________________

Welding? Who Needs Welding To Build a Jet?

[Mark 'Thixis', interviewed for jetZILLA by Mike Kirney]

Here's the other entry in our 'Cheapskate Homebrew Showcase':

Mark 'Thixis', another participant on Kenneth Moller's

pulsejet forum, has constructed an amazing array of simple

pulse combustors using only inexpensive steel pipe and cast

iron plumbing parts, mostly without precision machining. Mark

lives in the State of Florida, USA. Here he's interviewed for

jetZILLA by Mike Kirney [see my interview with Mike, above]

and answers some good questions for amateur pulsejetters:

jZ: How's the weather down south, Mark?

Mark: It's great, Mike! The Spanish Moss is hanging long and I

can eat my fish now instead of running my sled on it.

jZ: Uh ... I beg your pardon?

Mark: Read my forum posts -- you'll figure it out.

jZ: Um, OK ... I'll do that. You have quite a collection of

homemade jets. How long have you been experimenting with pulse

combustion?

Mark: I have been doodling with pulsejets for about 15 years.

|

THE 'THIXIS' FAMILY PORTRAIT

Except for the original DynaJet [the

engine with the red anodized valve head,

near the center of the photo], all these

are experimental engines and 'jam jar'

combustors Mark has built or modified

from such things as plumbing hardware

and medical implements [and, in some

cases, even glass jam jars!].

Photo Copyright 2003 Mark 'Thixis'

VIEW LARGE IMAGE

|

|

jZ: Wow! That's a lot of experimental experience. What got you

interested?

Mark: Long ago my brother gave me a Dynajet that he bought in

Texas for around $60.00. I didn't fire it up for several years.

Then I did, and was surprised at the noise. Later, in college,

I started to wonder if I could build one out of water pipe, and

it took me a few months of thinking and toying until I got one

to run.

jZ: What's the biggest jet you've ever built?

Mark: The biggest jet I attempted was a 4 inch plumbing pipe

which weighed over 40 pounds and was a beast which shook my

garage wall, along with all the things hanging on it, when it

fired. I cowered and decided the neighbors would complain if I

kept the cannon shots up.

jZ: Man! You're lucky you didn't get busted! Did it sustain

combustion?

Mark: No, the biggest I've gotten a continuous run from is

three inch diameter [75mm ID], thick-as-can-be threaded

water pipe.

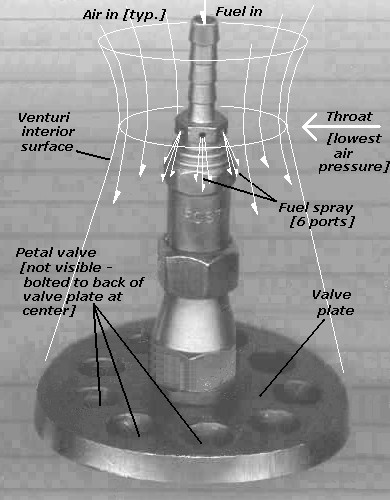

MARK'S BIG IRON

This is the 3-inch pipe engine

mentioned above. The valve plate

shown in this month's cover photo

and in the photos below are from

the front end of this engine, and

can be seen from the valve side at

the center of this shot. The reddish

object is the valve head of the

DynaJet, shown here for scale.

Photo Copyright 2003 Mark 'Thixis'

|

VIEW LARGE IMAGE

|

|

|

jZ: What fuel do you use in your jets?

Mark: I like to use methanol. It evaporates quickly and is very

forgiving with fuel/air ratios.

jZ: Tell me about your first jet. How much did it cost?

Mark: My first jet cost me about $10.00 in parts if you don't

count the spring steel, which was about $20.00 a roll, but you

can make a lot of reeds out of it.

jZ: A jet for thirty bucks US! What tools did you use to build

that thing?

Mark: The tools I used were a grinder, drill press, vise, pipe

wrench, and a tap for the spark plug. A very smooth edge can be

made on a valve plate by inserting a bolt in the middle of the

plate and rotating the disk against an edge in order to control

the distance.

|

A PLATEFUL OF HOLES ...

Mark's 'bench grinder machined' valve plate at the

bottom, with the fuel port assembly, built up out of

hardware store plumbing parts, bolted to the center.

The ring of nine holes in the plate lets air/fuel mixture

into the combustion zone when suction opens the thin

spring steel petal valves [see bottom view, next photo].

Photo Copyright 2003 Mark 'Thixis'

VIEW LARGE IMAGE

|

|

... AND A FLOWER OF NINE PETALS

Here's the valve plate back side, with the

nine valve petals clamped in place under the

retainer [the large washer in the center] --

the central bolt not only holds the retainer,

but goes clear through the plate to support

the fuel port assembly shown in the photo

above. The front side of the retainer is

dome-shaped to allow the petals to open

rearward and land on its smooth surface.

Photo Copyright 2003 Mark 'Thixis'

|

VIEW LARGE IMAGE

|

|

![The entire valve plate completed [brazed] (c) 2003 Mike Kirney](Mark_valveplate_detail_crop1_small.jpg)

|

jZ: Thanks for the 'machining' tip, Mark. The classic 21st Century

pulsejet is fabricated from thin guage stainless steel sheet. The

heat produced by operation can make these glow brilliant orange.

Does the thick steel wall of the plumbing pipe glow ever like that?

Mark: Even though they are very thick, they glow a dull red, and

if mounted on a board with nails to wedge it down, the board will

billow smoke from the heat.

jZ: Sounds dangerous! What about the zinc coating? Most plumbing

pipe is galvanized, is it not?

Mark: It is. Once I found a deposit at the tail of a 3 inch

diameter water pipe jet. It had formed or melted a ring of zinc

or something that I pulled out almost in one piece from the

galvanized plumbing pipe after it cooled down. I had previously

attempted to grind a flare in the tail [which didn't work with my

tiny grinding stones] so I know the ring wasn't there to begin

with. The ring of metal was soft and bendy.

________________________________________________________________

CAUTION! Precautions need to be taken when using galvanized or

cadmium plated steel in a pulsejet. When the steel gets red hot,

the galvanizing or plating will start to burn off -- the

smoke-like fumes from this are EXTREMELY hazardous to breathe.

When welding such materials, always provide adequate air

movement to keep these fumes away from your face [a small 'box'

fan is adequate] or better yet, work outside and orient the work

so the breeze immediately blows the fumes away from the weld

area. When running your jet the first few times, stay on the

upwind side so the smoke and fumes aren't blowing toward you.

When the engine has been hot enough long enough, the galvanizing

or plating will be completely burned off, so this hazard is

eventually eliminated. - Editor

_________________________________________________________________

|

NOW, A FEW SHAMELESS PLUGS

Mark's collection of ignition plugs that

he's used in various homebuilt engines.

Note that some of these are extensively

modified! [The three little plugs at the

left edge are model airplane glow plugs,

for scale. In general, little success has

been achieved by anyone trying to use

glow plugs for pulsejet ignition.]

Photo Copyright 2003 Mark 'Thixis'

VIEW LARGE IMAGE

|

|

jZ: What's the longest one of your jets has actually sustained

combustion?

Mark: The longest I ever ran one was for about 5 minutes, when I

decided to go ahead and let it run the tank dry.

jZ: That's a pretty decent run, as far as I can tell. Thanks for

dropping by to answer some questions for JetZILLA, Mark.

Mark: No problem, Mike. Hey buddy, do you have another beer?

jZ: More beer? Who do you think I am, Molson Breweries? Get outta

here!

Mark: OK, OK. Um ... would be it be alright if I left my truck

here overnight?

|

RUGGEDER THAN YOUR AVERAGE JAR

One part of Mark's pulsejet hobby is making up

'jam jars'. A jam jar is an 'almost pulsejet' which

sits upright with a small pool of liquid fuel at

the bottom, and runs by alternately firing and

breathing through a single small nozzle at the

top, after lighting with a match. Traditionally,

jam jar engines are made from a small glass jar

[or more recently, plastic bottle] with a metal

lid in which a small hole has been drilled or

punched. Mark likes his a little heftier; the

ruler on the left is a six-inch [approx. 16 cm]

rule.

Photo Copyright 2003 Mark 'Thixis'

|

|

_____________________________________________________

Photo Credits:

All photos in this article were provided by, and are property of,

Mark 'Thixis'.

_____________________________________________________

Mark 'Thixis' is a longtime pulsejet builder and experimenter

living in Florida, USA. No one knows what his last name really

is, and nobody knows what 'Thixis' really means. But, if you

want to contact him about this article, email: Thixis@aol.com

_____________________________________________________

|

![Setup of the valve plate [unbrazed] (c) 2003 Mike Kirney](Mike_setup_valveplate_crop1_small.jpg)

![The entire valve plate completed [brazed] (c) 2003 Mike Kirney](Mike_brazed_valveplate_crop1_small.jpg)

![The entire valve plate completed [brazed] (c) 2003 Mike Kirney](Mark_valveplate_detail_crop1_small.jpg)